MAKRO AERO Main Landing Gear (MLG) Trolley is meticulously engineered to support one of the most critical components of wide-body aircraft. Designed to securely hold, lift, lower, and position the Main Landing Gear during installation and removal operations, the MLG Trolley ensures precise handling for maintenance procedures. Compatible with A330, A340 aircraft models, it enables streamlined maintenance workflows with maximum efficiency. Built to meet industry-leading safety and quality standards, the MLG Trolley offers exceptional maneuverability and user-friendly operation. Its robust, yet efficient design ensures durability and reliability, making it an essential tool for demanding aviation maintenance environments

MAKRO AERO Removal and Installation Tool is reliable tool for the removing and installation processes of landing gear during heavy maintenance checks. Robustness, stability, effectiveness and versatility are distinct features of this tool.

The MAKRO AERO Nose Cowl Dolly is a highly versatile, lightweight tool engineered for precise removal and installation of nose cowls across a range of aircraft, from B737/A320 to A330. Its compact, ergonomic design ensures structural stability, minimizing vibrations and enhancing cowl protection during transport or maintenance. Integrated locking mechanisms provide secure cowl positioning, ensuring both safety and operational efficiency.

The Thrust Reverser Dolly is an engineered solution designed to streamline the handling and installation of engine components, enabling safe inversion during aircraft maintenance. Compatible with both Wide-Body and Narrow-Body aircraft, mitigating risks of damage or deformation due to improper handling during removal and reinstallation. Its shock-resistant design guarantees smooth and controlled operation. MAKRO AERO emphasizes the critical importance of using specialized tools for maintenance. Improper equipment invites component damage, increases the risk of engine part deformation, and extends maintenance turnaround times.

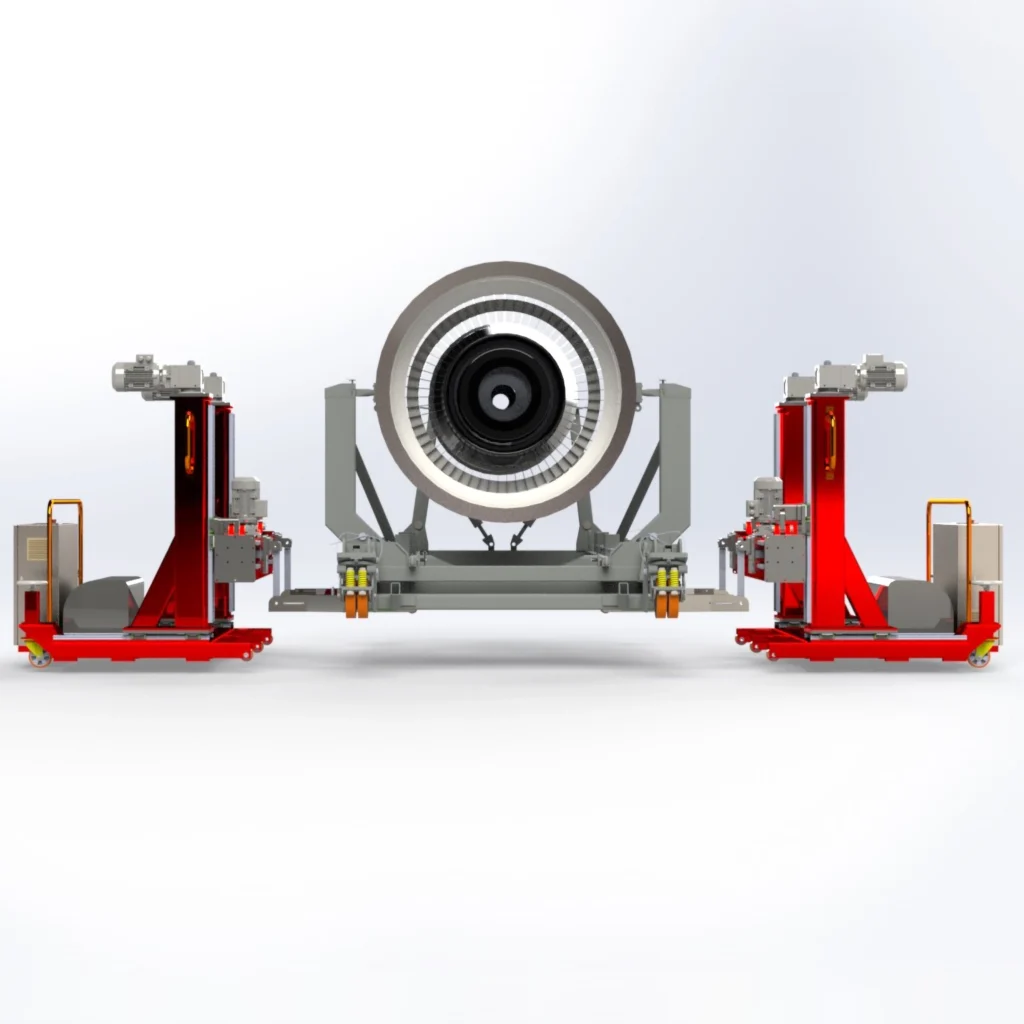

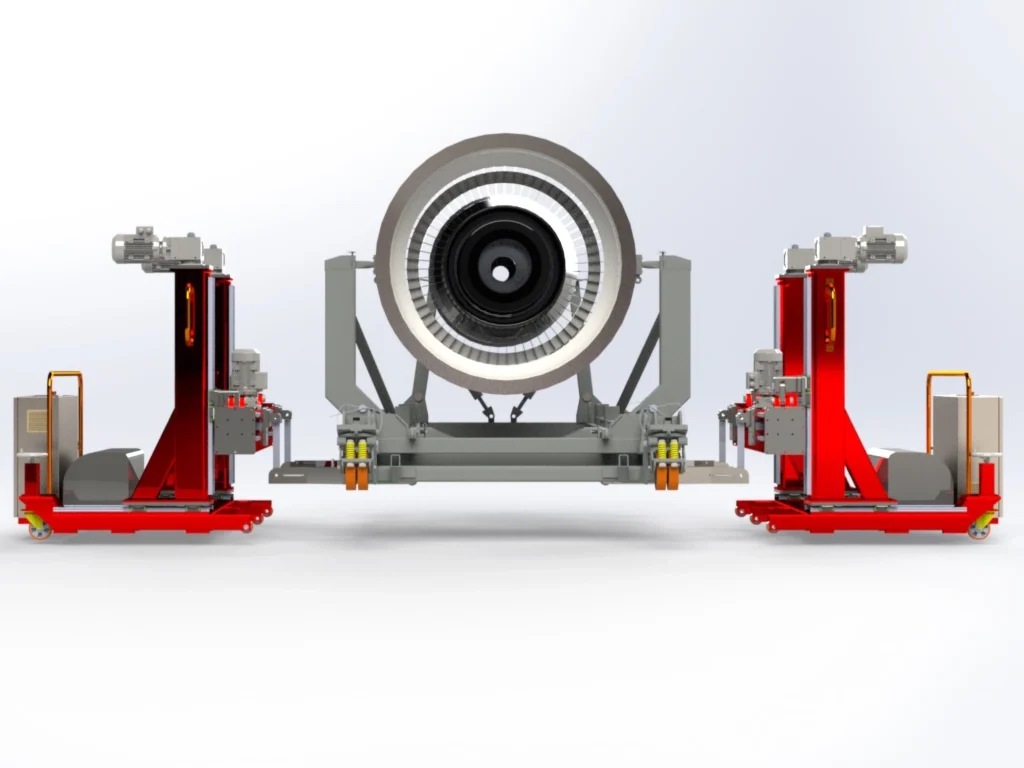

The MAKRO AERO Engine Positioner is expertly engineered to facilitate precise engine placement with minimal effort. This advanced positioning system ensures seamless alignment, reducing the need for multiple adjustments and eliminating unnecessary rework. Its precision control mechanisms enhance operational efficiency while mitigating risks of damage caused by repeated handling. By streamlining the engine installation process, it significantly improves both safety and productivity in maintenance operations.

The Fan Cowl Dolly is a specialized engine handling tool designed by Makro Aero for the safe transport and secure storage of fan cowls within maintenance facilities. Engineered for ease of maneuverability, it features robust towing capabilities, allowing technicians to efficiently relocate fan cowls with minimal effort. The fan cowl is securely fastened to the dolly using a streamlined locking mechanism, ensuring stability during movement. Equipped with heavy-duty caster wheels, the dolly is built to support significant loads, while its polyurethane construction minimizes vibrations, protecting the fan cowl during transit and storage.

The MAKRO AERO Tire & Brake Dolly simplifies tire and brake assembly tasks with its compact, ergonomic design, allowing one technician to complete the job without extra manpower. Suitable for wide-body and narrow-body aircraft, it ensures easy handling and durability, offering a range of models tailored to meet specific aviation needs.

Köseler Mh. 29.Sk. No:22 Mermerciler Sanayi Sitesi 41455 Dilovası / Kocaeli / TÜRKİYE

Copyright © Makro Aero 2024 | All Rights Reserved

Köseler Mh. 29.Sk. No:22 Mermerciler Sanayi Sitesi 41455 Dilovası / Kocaeli / TÜRKİYE

Copyright © Makro Aero 2024 | All Rights Reserved